Pre-Construction Consultation

A Gold Coast Pool & Spa designer/project manager will visit you and your family at your home to discuss your swimming pool project. Any questions or concerns can be answered at this time, and we will discuss all of your must have items to create the perfect outdoor environment for your family to enjoy for years to come.

Design/Site Plan

Gold Coast Pool & Spa will work hand and hand with our customers to design the most beneficial concept for their needs. We use 3D renderings & auto-cad drawings to simulate what your backyard will look like when the project is complete - so there are no surprises! This ensures you will be happy and satisfied with the finished product for years to come.

Permits and Approvals

One of the main components to building your new backyard oasis is gaining approval from the local municipalities. Gold Coast Pool & Spa will apply for an obtain all city & town permitting required to construct your project. All plans must comply with local and state building codes, and we will also handle all applicable inspections and final Certification of Occupancy.

Excavation

At this point your plans have been approved, your permits have been secured and the Gold Coast Pool & Spa team is ready to make your dream come true. The dig begins by forming out the inital shape of the future structure. Next, using transits and other engineering devices we will get all our exact elevations and depths to conform to the specifications of your plans. Lastly, a 3"-6" layer of gravel is installed, the gravel allows for proper drainage underneath the concrete shell of the pool.

Framing

Once excavation is complete framing begins and the pool starts coming to life. The framing sets the tone for the entire project. We ensure that the pool is perfectly level at this point as well as in proper orientation with house and all other structures.

Structural Steel

Our pool shells are constructed using 1/2 inch rebar as opposed to the 3/8 inch industry standard. We also use grade 60 rebar (50% stronger than grade 40). The reason for this is that it makes the pool shell that much stronger. We tie our steel 12 inches on center with 6 inch verticals in the deep end that tie into the horizontal runs in the re-enforced bond-beam. The steel is shaped to the pool’s design and extra steel is used at points of high stress. Lastly, the electrician will make all required bonding connections to the steel shell.

Plumbing

Rough plumbing or "stub-out" is performed immediately following steel installation. This includes the installation of all main drains, skimmers, light niches, & return lines - including spa plumbing if applicable. Our plumbing systems are designed using proven hydraulic techniques and principals that we have learned through years of hands on experience. We also pressure test multiple times throughout this process to ensure a leak-free, watertight shell.

Gunite

We then pneumatically apply the gunite over the steel reinforced cage. The gunite is a highly pressurized concrete that is hydrated at the nozzle during application, which results in lower moisture levels and less chance of slump. For this reason, it is up to ten times stronger than poured concrete. Our gunite shells come with a lifetime warranty for as long as you own your home, giving you piece of mind that Gold Coast Pool & Spa stands behind it's product.

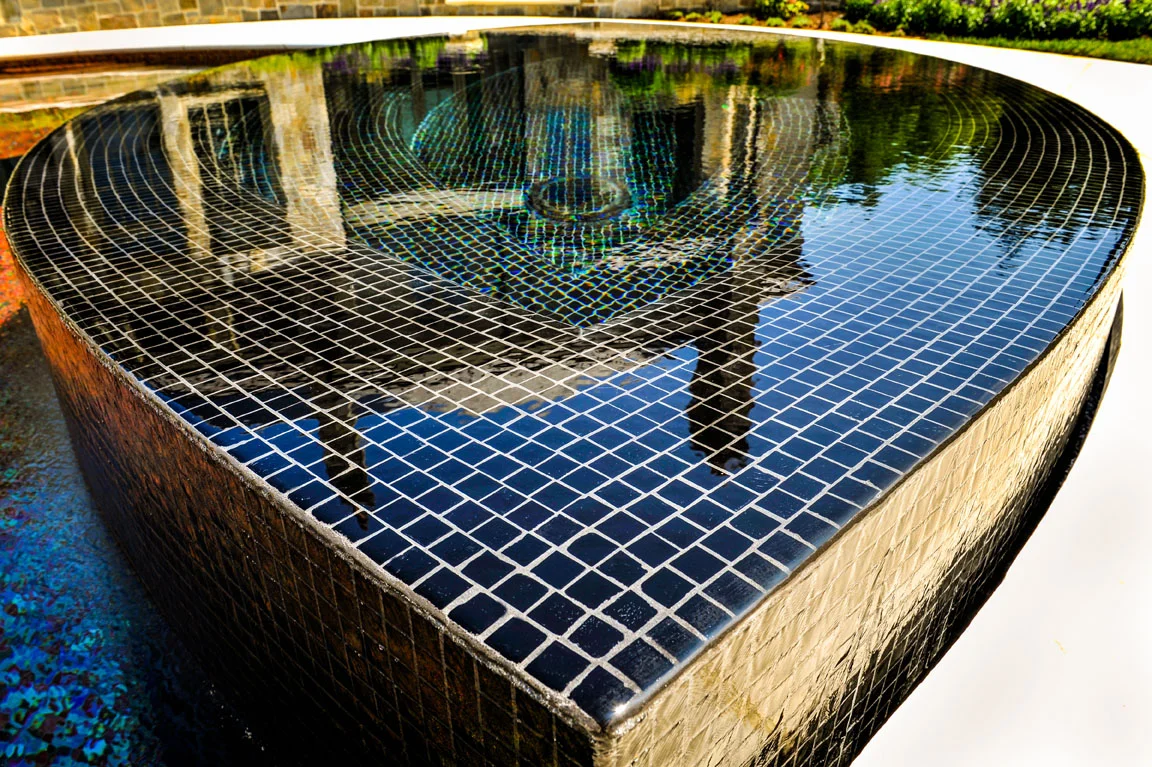

Tile & Coping

The next step in the construction process is the installation of your waterline tile and coping. Your pool will have a frost-free, weather resistant waterline tile that will be hand-laid and carefully grouted around the perimiter of your pool by a skilled craftsperson. The coping will be hand-laid and grouted on the bond-beam of your pool by the same craftsmen that set the tile.

Final Plumbing & Electrical

At this stage all pumps, filters, heaters, & chlorination systems are installed. The plumbing for each pool is designed specifically to give it the best circulation and filtration for crystal clear water and ease of maintenance. We perform hydraulic calculations to ensure that all equipment and piping are of the correct size to combine water clarity and energy conservation. In addition we run our plumbing lines side-by-side to avoid future breaks due to ground movement. The final electrical panel is installed and all pool equipment is wired up. Plumbing and electrical are now complete.

Plaster Finish

Undoubtably the most exciting part of the process. The pool interior is coated with your choice of plaster. Whether you choose a traditional marcite plaster or an upgraded DiamondBrite, RiverRok, or BeadCrete finish, our expert tradesman will ensure a quality job that will last for years to come. The first thirty days of your plaster define the lifespan, that is why there is no need to worry when you choose Gold Coast Pool & Spa. We will cure your plaster for the first thirty days to ensure your new investment remains as durable and aesthetically pleasing as possible for a long time to come. Our technicians are NPC (National Plasterers Council) certified in Swimming Pool Plaster start-up procedures.

Start-Up

Once full, a service technician will come out to your home and start all pool and/or spa equipment. Once the equipment has been started up and the pool is fully operational, our service manager will set up a time to come to your home and show you the functionality and operations of your new pool. This includes everything you will need to know about routine maintenance on the pool and some troubleshooting tips. If you do have questions or require technical support, our trained personnel are only a phone call away.